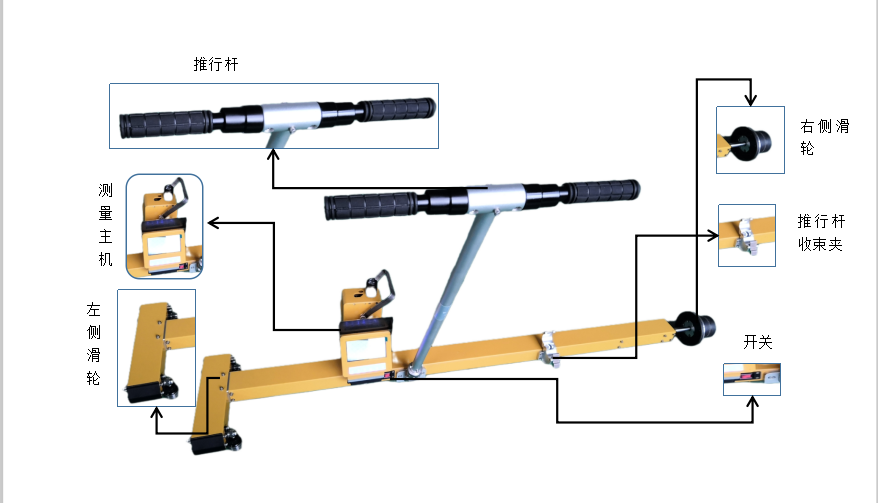

Product introduction:

The catenary geometric parameter automatic measuring instrument is a new generation product developed by our company in order to solve the problem of high labor intensity low efficiency of the high-speed railway catenary laser measuring instrument. The system adopts an all-digital signal video acquisition module. The industrial-grade camera directly displays the measurement positions on the 3.5-inch true-color screen. The device has a built-in infrared camera that can automatically track the catenary perform voice broadcasts around the clock. Compared with the traditional measuring instrument, the new generation of products can be used standing, no need to squat down to operate aiming reading. The device can realize automatic accurate measurement, automatic storage analysis, real-time transmission sharing of basic data of the contact network. It supports the seamless connection of tablets smart phones with 4G WIFI modules with the system, realizes remote storage analysis.

Features:

The built-in infrared camera is used for all-weather tracking identification of the catenary, the built-in high-frequency laser is used for high-precision measurement of the catenary.

The measuring instrument can measure automatically manually. The automatic measurement does need to bend aim manually, there is no need to change the position of the portable measuring instrument.

The whole equipment can be implemented standing on the track. During the implementation process, it can automatically track measure the lead height pull-out value of the contact net, the measurement data can be broadcast in real time.

The control panel of the measuring instrument adopts fully sealed touch buttons to realize the parameter setting input, manual measurement rotation fine-tuning, laser switch other functions.

The measuring instrument host can query the measurement data in the form of table record through the interval parameters alone, is equipped with dedicated PC software.

The connecting part between the track ruler the main unit should be made of high-strength stainless steel, should be made of easily damaged materials such as aluminum alloy, aluminum, nylon.

The base can be rotated 45 degrees with one hand to realize the installation of one part in place, the automatic locking automatically removes the electrode oxide layer, the mechanical electrical components are connected reliably.

The whole machine should meet the requirements of railway field inspection operations, the battery is built in the instrument, the whole surface is treated with ceramic spray technology.

Technical Parameters:

number | project | Measuring range (mm) | Precision |

1 | Lead height | 3000-15000 | ±2mm |

2 | Pull out value | ±1200 | ±4mm |

3 | Branch center projection | ±4mm | |

4 | gauge | 1410-1470 | ±1mm |

5 | Outer rail super high | ±150 | ±2mm |

6 | Side limit | ±2mm | |

7 | Red line elevation | ±3mm | |

8 | Locator slope | 1:n | nto0.1 |

9 | Strut span | 0.5m-100m | ±0.5m at 100m |

10 | Height difference of contact line of load-bearing cable | ±3mm | |

11 | battery | Two 9600mAh lithium batteries, one spare battery | |

12 | weight | The main machine is more than 3.5kg, the track ruler is more than 9.5kg | |

Sichuan Xinda Rail transportation Equipment Co., Ltd

Mobile: 15681986617

Website: www.xdailway.com

Email: scxd@vip.163.com

Xinda post: w621000

Tel: 0816-2349834

Address: No. 507, building 2, innovation center, science Technology Innovation Zone, Mianyang City

Scan pay attention to us