Present situation 1. The monitoring equipment is scattered, which leads to high cost inconvenient use. 2. It was only after an accident that we found out the problem. 3. The overall monitoring level of OCS is too low to ensure the safety reliability of high-speed railway. 4. Too many installation lines of monitoring equipment, unsafe OCS. 5. No big data to analyze the cause of failure. | Requirement 1. Integrated analysis of centralized management, low cost easy to use. 2. Early warning in case of failure. 3. The overall monitoring level of OCS is improved to ensure the safety reliability of high-speed railway to a large extent. 4. Wireless data transmission, solar power, safe convenient. 5. Use big data to analyze the cause of fault comprehensively, provide complete data for improving the overall monitoring level of OCS. |

Solution On line monitoring device for catenary catenary tension Line branch current monitoring device Pole slope monitoring device Catenary structure compensation efficiency monitoring device Video monitoring device |

|

Acquisition device ■ convenient installation: independent solar powered wireless data transmission. ■ rich data: provide rich collectors rich data sources for the system. ■ choice of diversification: it can be used separately at the same time, which is suitable for different scenarios. ■ modular design: good versatility, low failure rate, up to 10 years of service life. | Centralization device ■ convenient installation: independent solar powered wireless data transmission! ■ centralized processing: data of all collectors can be centralized within 600mm radius for centralized transmission. ■ cost reduction: multiple collectors only need to be equipped with one concentrator to reduce the use cost. |

Cloud services ■ service stability: use Alibaba cloud services to ensure service stability provide a solid foundation for big data. ■ easy to use: it can be used directly through browser without additional software installation. ■ flexibility: in addition to using the browser, it is equipped with a mobile browser, which can be used directly by the mobile phone. | Railway intranet server ■ through the network data collection terminal, the internal network the external network are completely isolated to ensure the data security. ■ the railway Intranet can still check the collected data through browser mobile phone. |

system composition

The system is mainly composed of data collector, data concentrator, data transmission link, data monitoring center, user PC mobile terminal.

The data collector adopts the power supply mode of solar cell + high-performance polymer battery + super capacitor, making full use of the micro power consumption technology so that the whole system can need additional wired power supply circuit for a long time, greatly integrate the solar panel the concentrator, making the installation more simple; then through the radio-frequency way, the collected data will be transmitted to the concentrator regularly. The data concentrator is powered by advanced physical energy storage technology (graphene energy storage system), with long service life (up to 50 years), excellent deep discharge performance stable power output in ultra wide temperature range. the collected data is transmitted to the data monitoring center through GPRS.

Data monitoring center, using Alibaba cloud as the data center, with a stability of 99.9%

User PC, using BS framework, using browser access, no need to install additional software. Mobile terminal can directly access data through mobile phone, realize mobile office, in addition, alarm notification can be carried out through SMS.

The system has applied for national invention patent accepted it, is currently in the process of examination.

Composition of collector

■ through real-time measurement of insulator leakage, current, meteorological conditions, statistics of leakage current in unit time, comprehensive temperature humidity other meteorological parameters, using expert analysis system, quantitative analysis is carried out to get the current pollution degree of insulator surface, provide accurate early warning information, timely understand the safety reliability of operating insulator.

■ cable shield monitoring device - it can monitor six cable shields at the same time, which can monitor the high-voltage cable shield in real time; in case that the current exceeds the limit, the outer sheath of the grounding current can send out an alarm message.

■ the catenary catenary catenary tension online monitoring device can effectively judge the broken line position. I: provide technical reference emergency repair guidance for catenary maintenance.

■ line branch current monitoring device: it is used to detect the branch current of catenary, monitor the line short circuit fault, ground fault, disconnection other items.

■ pole slope monitoring device: device for OCS broken pole, etc. ■ pole accident prevention monitoring I ■

Risks faced by OCS

Pollution leads to insulation, edge current discharge

Geological disasters, traffic accidents, mountain landslides lead to broken poles!

Poor contact of electric connector! Fire!

Weather disaster! Flood control!

Can't judge the field fault remotely!

Key points cannot be checked in real time!

Ratchet stuck! Falling flowers are abnormal!

High precision clamp resistance sensor is used to monitor the temperature of electrical connection eliminate potential safety hazards. Through the analysis of the temperature change curve, the analysis of the technical state of the electric connection is realized to check whether the connection is good.

Catenary structure compensation efficiency monitoring device: transmitting ultrasonic signal feedback

Video monitoring device: the video monitoring device at the top of the pillar can detect when the system fails

Operation interface

Pc terminal

Realize the management of basic data, configuration management of remote device, timing acquisition display of data, data over limit alarm, comprehensive data analysis, data storage, statistics query management. It can send alarm information to the preset mobile phone. The software interface is friendly, simple easy to operate, the whole interface is clear at a glance, full of sense of technology.

Mobile phone end

The on-line monitoring system of catenary power supply equipment can realize data management, data collection, data display, data comprehensive analysis, statistics query management, equipment operation status display at the equipment through handheld mobile data terminal (smart phone tablet computer). When the mobile data terminal can communicate with the monitoring center through GPRS 4G network, it can communicate with the concentrator through WiFi on site to realize data collection, analysis, statistics management.

Overview

As an important part of railway power supply safety detection monitoring system (6c system), the ground detection device (C6) of catenary power supply equipment monitors the operation status of catenary power supply equipment in real time, guides the maintenance of catenary power supply equipment. Our company uses MMP tracking technology, dynamic power management, cloud server other technologies to realize the device's independent solar power supply independent wireless transmission network, establishes a wireless sensor network platform with low power consumption, which can be used for the tension isolation of catenary wire Online integrated monitoring video monitoring of edge leakage current, electric connection temperature, pillar tilt (vibration), pillar longitude latitude, compensation device a b values, vibration of contact line, site environment (condensation, ice, flood control other meteorological monitoring conditions), branch current (short circuit direction location), cable shield insulation other parameters, To achieve the comprehensive real-time monitoring of catenary state parameters, the device is designed for maintenance free, the design life is less than 10 years.

The data collected by the equipment is recorded in the form of waveform, the self defined interval time is sent the overrun parameters are sent to the ECS immediately. The real-time monitoring of the equipment status is realized by using PC browser mobile phone. The equipment adopts modular design, convenient maintenance, stable operation, ensures the power supply safety of the contact network.

The OCS power supply equipment online monitoring system of our company is mainly divided into the following parts: system monitoring center, OCS catenary tension monitoring device, insulator leakage current monitoring device, electric connection temperature monitoring device, pillar slope monitoring device, OCS compensation device B value monitoring device, OCS vibration monitoring device Equipment, field environmental monitoring device, line branch current monitoring device, cable shield insulation monitoring device, mobile phone terminal, solar power supply voltage monitoring, data concentrator, video monitor. Each part is connected coordinated with each other.

Our characteristics

centralization

Get rid of the state of various detection devices fighting for their own, unified monitoring centralized management

wireless technology

Wireless transmission between collector concentrator, concentrator data center, without complicated cables

Micro power consumption independent power supply

Micro power consumption ensures that the equipment can be online for a long time, independent solar power supply, without additional power supply

stability

· each collector adopts modular design the same mode (solar power supply unit + MCU + sensor + RF unit), with good universality low failure rate. Components with a service life of more than 10 years are used to ensure maintenance free

Low cost

・ save labor inspection cost, share equipment resources, share one concentrator with multiple collectors for data return

Modular design

Data concentrator

Through the data concentrator, the system can upload the data of multiple collectors to the monitoring center transmit it to each collector under the command of the monitoring center, so as to realize reduce the cost of the whole system. The communication distance between the collector the collector can be extended through the relay mode; the communication distance between the collector the collector between the collector the collector between the collector the collector The concentrator communicates with the monitoring center through GPRS 4G network through the Internet.

Solar power supply voltage monitoring

The power supply of the system adopts the power supply mode of graphene photovoltaic power supply device + solar cell + high-performance polymer battery, making full use of the micro power consumption technology, so that the whole system can be long-term without additional wired power supply lines. Each unit of the system monitors uploads the current voltage in real time so that the relevant staff can know the voltage of each unit at any time

Graphene photovoltaic power supply device adopts physical energy storage technology, which has the characteristics of long service life, excellent deep discharge performance stable output power in ultra wide temperature range. It is specially designed for data concentrators with large power consumption.

Parameters of graphite photovoltaic power supply Rated voltage Rated capacity Large DC internal resistance Large leakage current working temperature Storage temperature High charging current Large discharge current Capacity change Life | 10.8V 240wh 3.2mQ 5.0mA -40。6 5。。 -40°C~70°C 100A 500A ( IS ) ±10% No less than45000h |

|

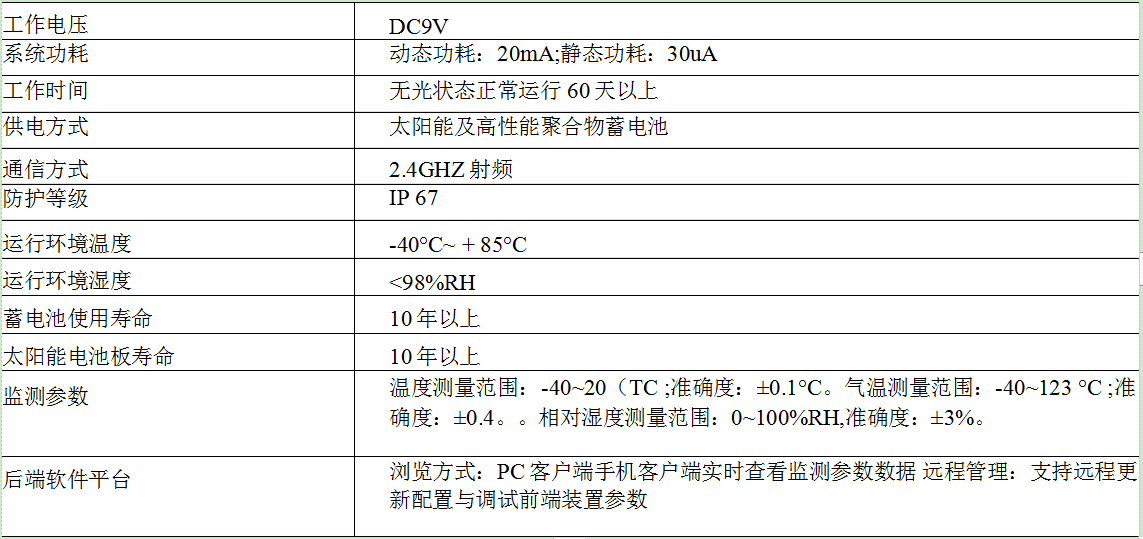

On line monitoring device of catenary bearing element tension

N-pillar slope monitoring device

The device is installed on the catenary cable powered by solar energy. The tension of the catenary cable can be monitored online the technical status of the catenary can be mastered by using the side pressure detection technology, anti-interference technology micro power consumption technology. Through the wireless transmission network, the monitoring data can be sent to the PC computer mobile phone client of the power supply section, which can be disconnected Make effective judgment on the location to provide technical reference emergency repair guidance for OCS maintenance.

| 参数

|

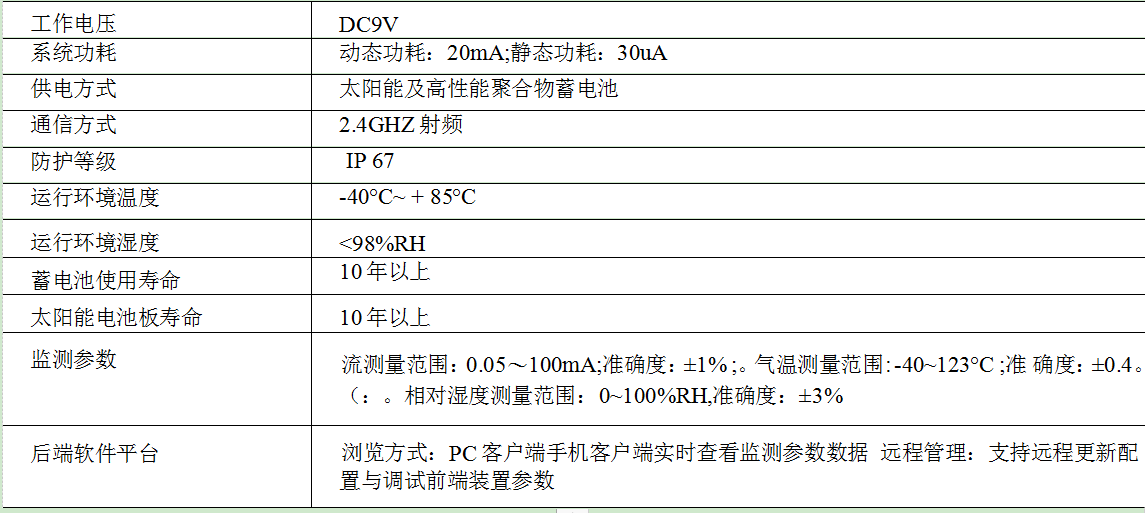

Line branch current monitoring device

The equipment is used to detect branch current of catenary, monitor short circuit fault, ground fault, disconnection other items. Two way transmission function, the terminal can call out view new data at any time, reduce the labor intensity of the staff, shorten the power outage time, reduce the power loss, improve the automation information of OCS operation.

| parameter Applicable voltage level Applicable compliance current Large fault current allowed Time for short circuit identification Load measurement accuracy Working environment temperature Protection level | 35kV 10-1000A 20kA/4S 0.02~5s ±3% -40°C~ + 75°C IP 67 |

Pole slope monitoring device

The device aims at the accident prevention monitoring of the broken pole other pillars of the catenary. The serial output dual axis inclination sensor for measuring the inclination angle is changed into a device for measuring the inclination angle of the pillars of the catenary, which is designed by the serial output dual axis inclination sensor.

| parameter measuring range Measuring axis Resolving power accuracy insulation resistance Waterproof grade | ± 30 (for H-shaped steel column) X axis Y axis Zero point zero two Zero Point Zero Five less than 100 megohm IP 67 |

R catenary compensator b value monitoring

The distance signal is obtained by the time difference between the ultrasonic signal the feedback signal. After being processed by the high-speed chip, it is converted into the required signal voltage to measure the b value of the catenary compensation device. The device judges the tension change of the catenary wire by the change of the AB value the environmental factors, judges the change of the tension change of the catenary wire with the temperature, so as to judge the work Whether it is normal . The video monitoring device at the top of the pillar can check the status of ratchet drop head in case of system failure.

Teaching learning 0.3~4m -20°C~ + 60°C 30 degrees up down 15 degrees 2mm | measuring range working temperature Beam wave angle measurement accuracy |

Video monitoring device

The video monitoring device at the top of pillar can check the status of ratchet drop head in case of system failure.

|

|

微型气象监测装置

|

|

On line monitoring device of electric connection temperature

The device is installed with special section of contact network (such as wire clamp), high-precision clamp resistance sensor is used for electric connection temperature monitoring to eliminate potential safety hazards. Through the analysis of the temperature change curve, the analysis of the technical state of the electric connection is realized to check whether the connection is good. Through the wireless transmission network, the monitoring data is sent to the PC computer mobile phone client of the power supply section, providing technical reference for the maintenance of the contact network. Wireless mode is adopted, which does affect high-voltage insulation, sensor is passive, without battery, high safety, good real-time temperature measurement, online temperature measurement temperature change monitoring at any time. Easy maintenance, long battery life, basically maintenance free after installation. |

|

On line monitoring device for insulator leakage current

Through real-time measurement of the leakage current meteorological conditions of the insulator, statistics of the leakage current in unit time, comprehensive temperature humidity other meteorological parameters, using the expert analysis system, quantitative analysis is carried out to get the current pollution degree of the insulator surface, provide accurate early warning information, timely understand the safety reliability of the running insulator. Early warning alarm shall be carried out in a variety of ways for the insulator exceeding the standard in time to guide the maintenance cleaning. The device is installed on the low-voltage side of the cantilever insulator, adopts the mutual inductance micro current detection technology to monitor the leakage current of the insulator, so as to realize the early warning of the pollution of the insulator. Through the wireless transmission network, the monitoring data is sent to the PC computer mobile phone client of the power supply section, providing technical reference for the maintenance of the contact network. The device is suitable for various lines, pole types, insulators, safe reliable, flexible communication, multi-user simultaneous detection support, high anti-interference ability. |

|

Cable shield monitoring device

The system has the advantages of simple structure, convenient installation high sensitivity. It can monitor six cable shields at the same time. It can monitor the outer sheath of grounding current of high-voltage cable shield in real time. When the current exceeds the limit, it can send out alarm message. The system has stable performance can intelligently analyze whether the equipment in the system is normal , can send out alarm information when it is abnormal.

'long service life, no maintenance in one overhaul period. Through GPS / 3G / 4G remote connection to the monitoring center, the system can quickly inform the alarm platform. It can continuously real-time monitor the capacitance current in the running state. The data of online monitoring is continuous can be regarded as a time series. Through the establishment of autoregressive moving average model of time series statistical analysis, we can judge the aging trend of cable insulation, judge whether the new monitoring value has significant changes, so as to correctly judge the aging reduction degree of cable main insulation.

|

|

Sichuan Xinda Rail transportation Equipment Co., Ltd

Mobile: 15681986617

Website: www.xdailway.com

Email: scxd@vip.163.com

Xinda post: w621000

Tel: 0816-2349834

Address: No. 507, building 2, innovation center, science Technology Innovation Zone, Mianyang City

Scan pay attention to us